Features

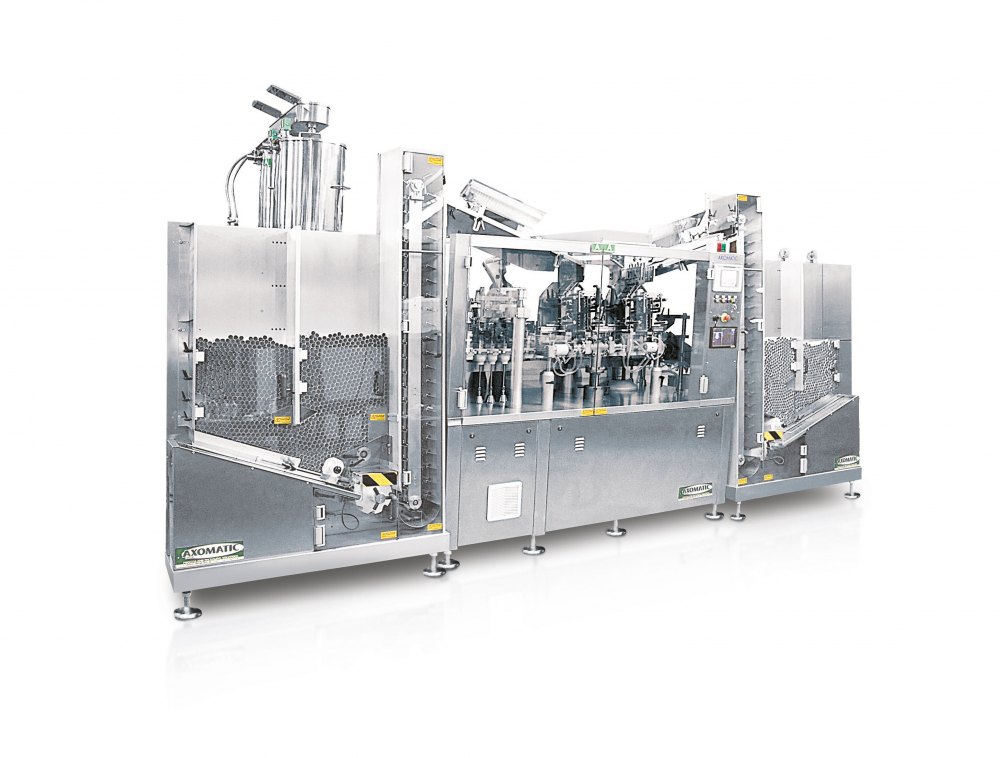

Automatic Tubes Filling and Closing Machine capable of filling liquid, semi viscous and viscous products into collapsible metal, plastic and laminate tubes.

- Machine body covers, electrical cabinet completely in Stainless Steel AISI 304L

- Electric control cabinet integrated in the machine perimeter, with easy access to all machine devices

- Two ergonomic tube loaders of big capacity for feeding tube from tray

- Control panel touch&screen with all the main functions, suitable for Industry 4.0

- Four independent dosing groups made in Stainless Steel AISI 316L, driven by separated servomotors

- Easy cleaning of all parts in contact with the product

- Four diving nozzles for an accurate dosage of the bottom of the tube, adjustable stroke 120 mm

- New hot air sealing system with low air consumption

- Possibility to realise customised sealing systems

- Number of turntable stations: “48”

- Machine in compliance with CFR 21 PART 11 with audit trail (option) C.I.P.

- System for the dosing groups (option)

- Full Atex certification (option)

Technical data

|

Speed |

275 pieces per minute |

|

Dosing range |

Between 3 and 250 ml |

| Tube diameters |

13,5-50 mm |

|

Tube heights |

70-220 mm |

|

Stations |

48 |